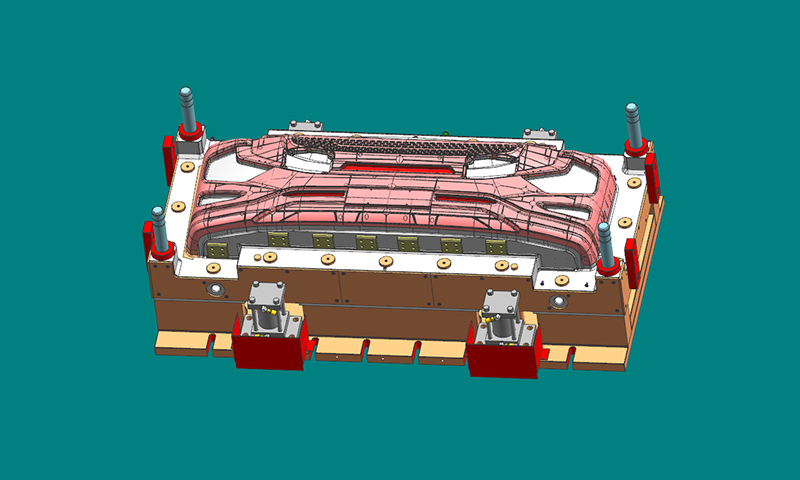

Mold design refers to the personnel engaged in digital design of enterprise mold, including cavity mold and cold stamping die. On the basis of traditional mold design, digital design tools are fully used to improve the quality of mold design and shorten the cycle of mold design.

Mold is a kind of industrial product which can form materials in a certain way with a specific structural form. At the same time, it can also batch produce industrial product parts with certain shape and size requirements. Almost all industrial products, from airplanes and automobiles to tea cups and nails, must be molded by molds. The high precision, high consistency and high productivity of the products produced by mould are incomparable to any other processing method. The quality, benefit and new product development ability of the products are determined by the mould to a great extent. Therefore, the mould has the honorary title of the mother of industry.

And molder is a high efficiency mold design software. It is a secondary development software based on UG (NX) platform, which is independently developed by Japan Telecom International Information Service Co., Ltd. In China, it is the general agent of its subsidiary Shanghai Diantong Information Service Co., Ltd. What problems can moldplanner solve in mold design? First of all, through the mold design consultant function, it can provide automatic mold separation, ejector pin layout design and cooling layout design consulting function, which solves the problem of poor design quality caused by the lack of experience in mold design. Secondly, through automatic placement of thimble, cooling parts, automatic drawing and report function, a large number of simple and boring working hours in mold design are reduced, and the work efficiency is greatly improved. Finally, through the registration of standard parts library, standard mold base library, through the registration of enterprise's own parts library and mold base library, the standardization of mold design is realized, and the negative impact of mold design caused by uneven technical level of mold designers and high turnover rate is solved.

Mobile Website

Mobile Website